dd Dual-Drain

(Distortion-free Screen)

Engineered : Core Engineering Principles

Our unique ‘dd’ system connects the screen without distorting, twisting or mechanically stressing the precision-laid screen, which can all cause measurable performance anomalies.

The Process

We have invested in machinery to quickly and efficiently perform a number of the key stages in our manufacturing process.

But working with our dual-drain system is one of those instances where there’s no substitute for the experience of a skilled operator.

Atlas ‘dd’ (Dual Drain)

Normally screened cables suffer from screen distortion when they are prepared for production. (If you’ve ever wired a plug or connector which uses a screened cable, you've done this yourself, cutting back and probably twisting the screening braid for termination). This distortion of the screen has a measurable impact, effectively changing the impedance and therefore the performance of the cable.

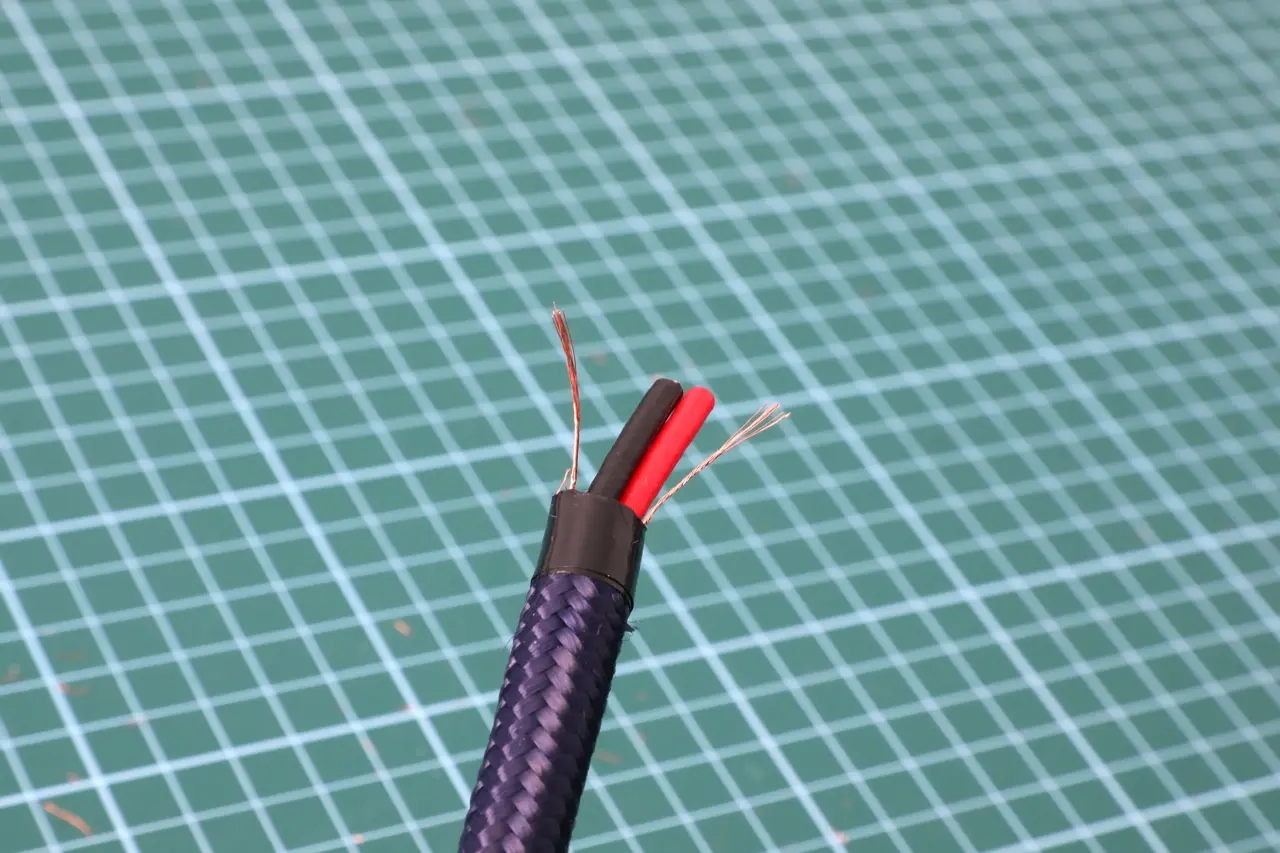

Our ‘dd’ configuration is based on a simplified version of the techniques originally developed for our Mavros and Asimi interconnects. Twin symmetrical drain wires (each attached to 180° segments of the plug) are inserted between a 100% copper/Mylar™ foil and screen.

The unique dd system connects the screen effectively to the cable return/plug interface, meaning the cable can be terminated without distorting, twisting or mechanically stressing the precision-laid screen. The benefits are in maintaining a consistent low impedance load to the plug, and a total 360° screening against noise and signal loss caused by RFI (Radio Frequency Interference).